Apejuwe

ọja Apejuwe

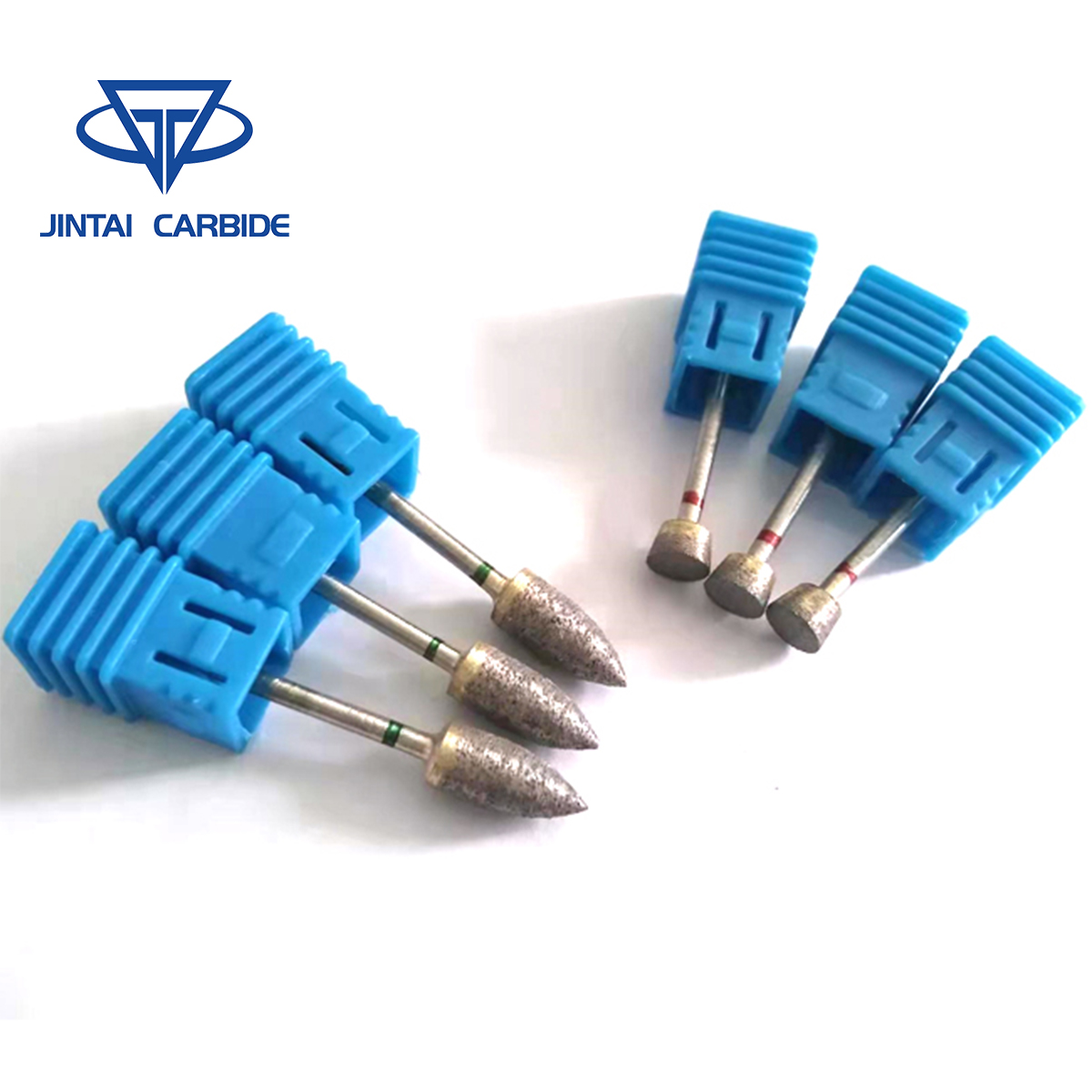

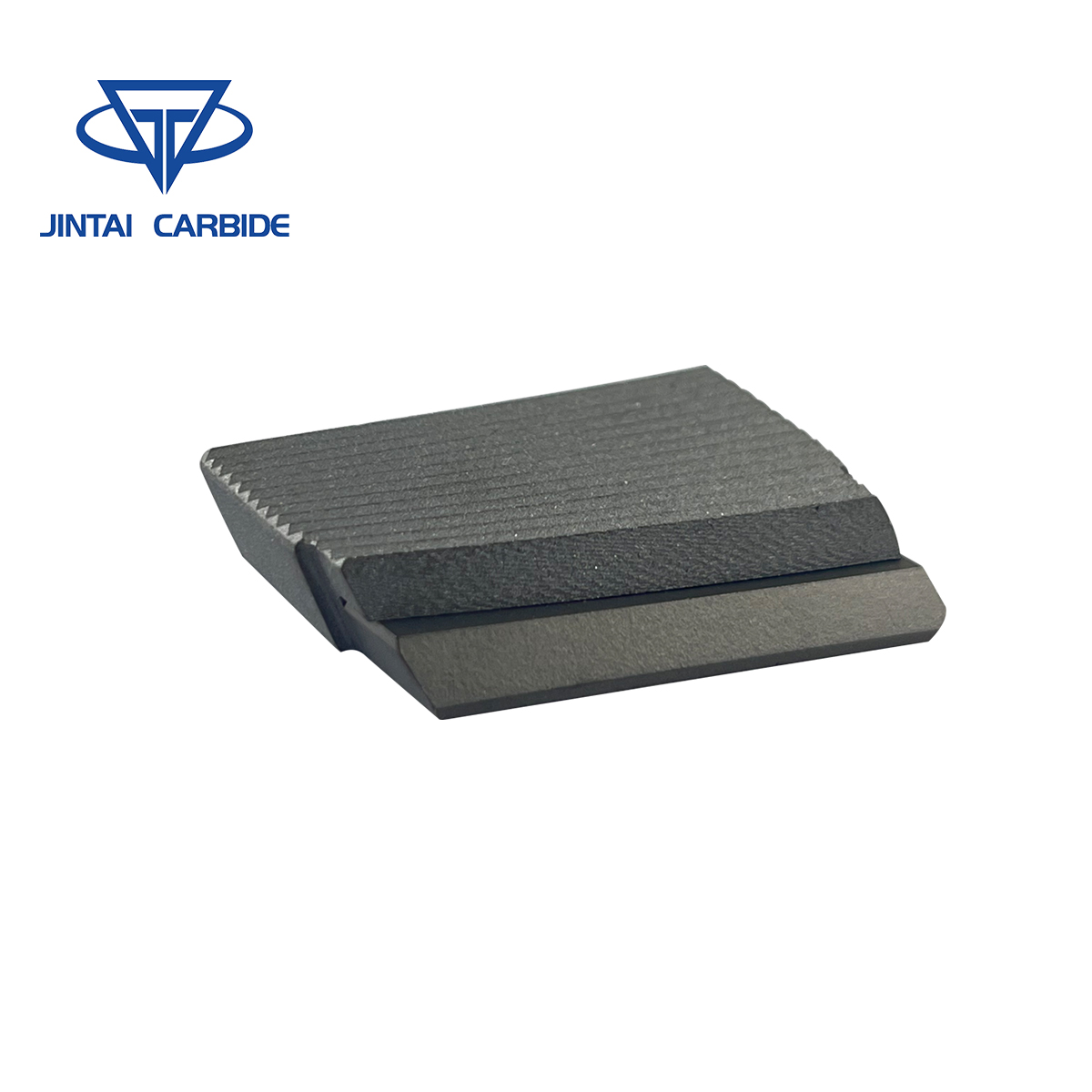

Ọpa carbide ti simenti ni taara ti o dara, lile ti o dara julọ, ati lile iduroṣinṣin.

Awọn ọlọ ipari, awọn olutọpa ati awọn gravers ni a gbaniyanju.O tayọ išẹ fun ga iyara gige.Dara fun gige irin lile, aluminiomu alloy ati Titanium alloy.A pese aṣa ti a ṣe, apẹrẹ-nẹtiwọọki-nẹtiwọọki, awọn ṣofo ti a fi sii Ere ni carbide simenti - ti a tun mọ ni Tungsten carbide tabi carbide to lagbara.

Iṣakojọpọ ohun elo:

1.Awọn ohun-ini ti ara:

A) Lile ti o tobi ju tabi dogba si 92.8 HRA;

B) iwuwo tobi ju tabi dogba si 14.2 g/cm³;

C) TRS tobi ju tabi dogba si 4200 N/mm²;

D) Ọfẹ ti ipo alakoso ETA;

E) Ko si ibajẹ nipasẹ awọn ohun elo miiran;

F) Porosity = A00 / B00 / C00;

G) Aṣọṣọ ati iwọn ọkà ni ibamu.Ko si iwọn ọkà le jẹ tobi ju pato lọ.

H) Chromium carbide onidalẹkun idagbasoke ọkà nikan.

2.Gbogbo awọn iṣelọpọ, awọn ohun elo ti a lo ni Germany, Siwitsalandi, ẹrọ isise;

3.It's dabaa gige kere ju 60HRC;

Ẹya ara ẹrọ

1. 100% wundia aise ohun elo.

2. Orisirisi iru ti onipò ti wa ni availalbe da lori onibara ká elo.

3. a ni laini iṣelọpọ ilọsiwaju ọjọgbọn ati awọn ohun elo ayewo lati rii daju awọn ọja to gaju.

4. Ilẹ konge ati ilana didan giga

5. Giga yiya resistance, ga líle ati ikolu toughness

6. Imọ-ẹrọ to ti ni ilọsiwaju, lilọ kongẹ.

Ipele Akojọ

| Ipele | ISO koodu | Awọn ohun-ini Mechanical Ti ara (≥) | Ohun elo | ||

| iwuwo g/cm3 | Lile (HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | Dara fun ẹrọ konge ti irin simẹnti ati awọn irin ti kii ṣe irin. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | Dara fun machining konge ati ologbele-pari ti simẹnti irin ati ti kii-ferrous awọn irin, bi daradara bi fun processing ti manganese irin ati ki o parun, irin. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | Dara fun ologbele-ipari ati ẹrọ ti o ni inira ti irin simẹnti ati awọn ohun elo ina, ati pe o tun le ṣee lo fun ẹrọ ti o ni inira ti irin simẹnti ati irin alloy kekere. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | Dara fun inlaying ipa rotari liluho apata ati rotari ipa apata liluho die-die. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | Dara fun inlaying chisel-sókè tabi conical eyin die-die fun eru-ojuse apata liluho ero lati koju lile apata formations. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | Dara fun idanwo fifẹ ti awọn ọpa irin ati awọn paipu irin labẹ awọn iwọn funmorawon giga. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | Dara fun ṣiṣe stamping kú. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | Dara fun ṣiṣe titẹ tutu ati titẹ tutu ku fun awọn ile-iṣẹ gẹgẹbi awọn ẹya boṣewa, awọn bearings, awọn irinṣẹ, ati bẹbẹ lọ. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | Dara fun machining konge ati ologbele-ipari ti irin alagbara, irin ati gbogbo alloy irin. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | Dara fun ologbele-ipari ti irin alagbara ati irin alloy kekere. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | Dara fun ẹrọ titọ ti irin-orisun, nickel ti o ni iwọn otutu ti o ga julọ, ati irin ti o ga julọ. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | Dara fun gige iṣẹ-eru ti irin ati irin simẹnti. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | Dara fun machining konge ati ologbele-ipari ti irin ati simẹnti irin. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | Dara fun ẹrọ titọ ati ipari ologbele ti irin ati irin simẹnti, pẹlu iwọn ifunni iwọntunwọnsi.YS25 jẹ apẹrẹ pataki fun awọn iṣẹ milling lori irin ati irin simẹnti. |

| YC45 | P40/P50 | 12.5-12.9 | ≥90 | ≥2000 | Dara fun awọn irinṣẹ gige ti o wuwo, n pese awọn abajade to dara julọ ni yiyi ti o ni inira ti awọn simẹnti ati ọpọlọpọ awọn ayederu irin. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | Dara fun inlaying Rotari ipa apata liluho die-die ati liluho ni lile ati ki o jo lile apata formations. |

Ilana ibere

Ilana iṣelọpọ

Iṣakojọpọ